Principle of weighing

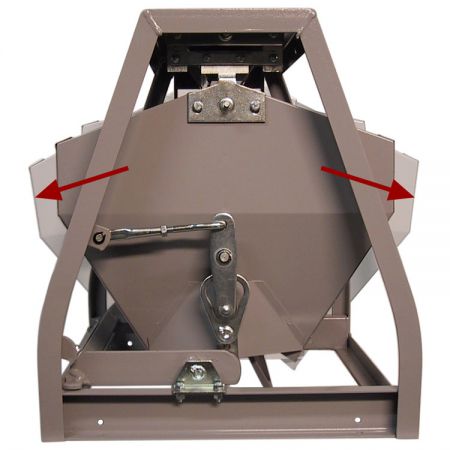

Diplomat batch weighers are based on the continuous batch weighing system according to which the material flows constantly through the weigher at a given capacity.

The continuity of the flow is possible without starting and stopping the auger or elevator which ensures a high capacity.

Weighing is based on the well-known principle of establishing physical balance between the batch weighed out and the setting of the weigher.

This ensures optimum accuracy irrespective of the nature and type of material.

Contrary to electronic load cell systems the principle relies solely on the force of gravity. No need for external power like electricity or air pressure. The function of the weigher is not affected by heat/cold or damp/dryness.

All data is either read on a mechanical counter fitted on the weigher or on an electronic battery counter. The data can also be transferred by a microswitch to other external units of measurement.

The weigher can therefor act as an essential control unit in a complete transport system both in terms of time and quantity.

What can be handled

The weighers are suitable for weighing out grain and other granules with a particle size not exceeding 25mm as well as ground materials. They are unfit for fine meal and other substances liable to arching.

The weigher can be custom fitted for use with other materials; as different tasks as weighing live trout brood and potato sorting are managed daily by Diplomat weighers.

Where to use

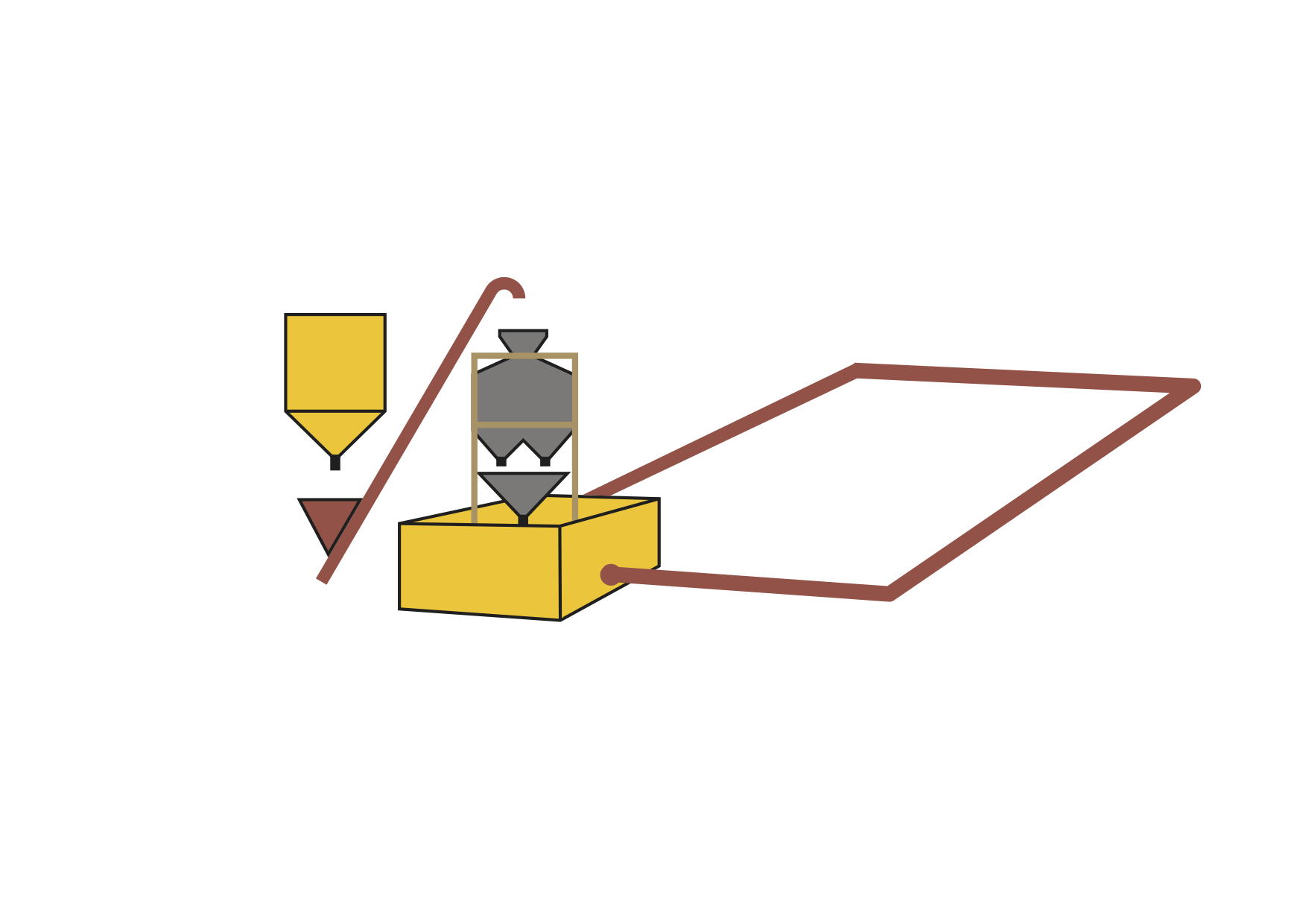

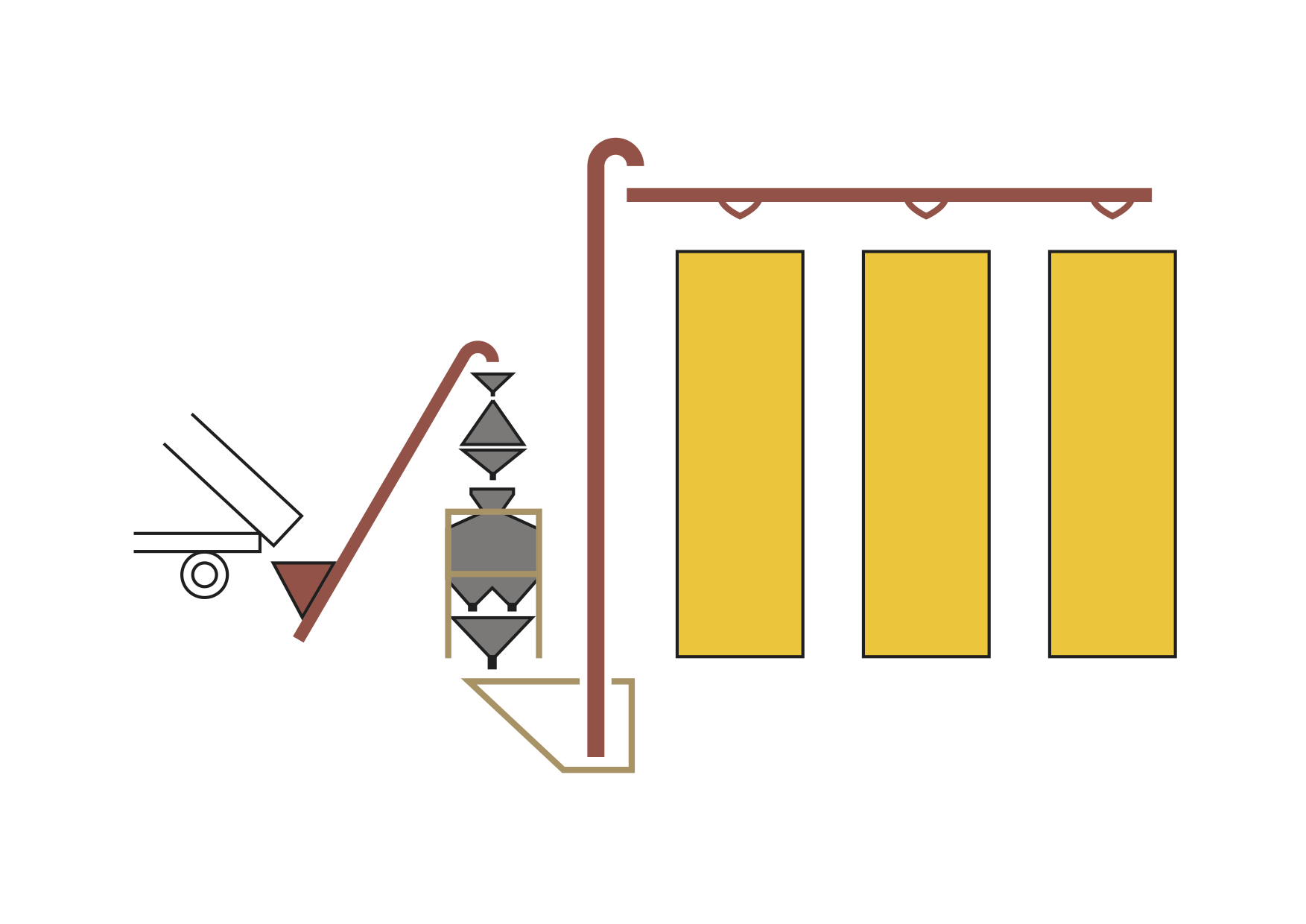

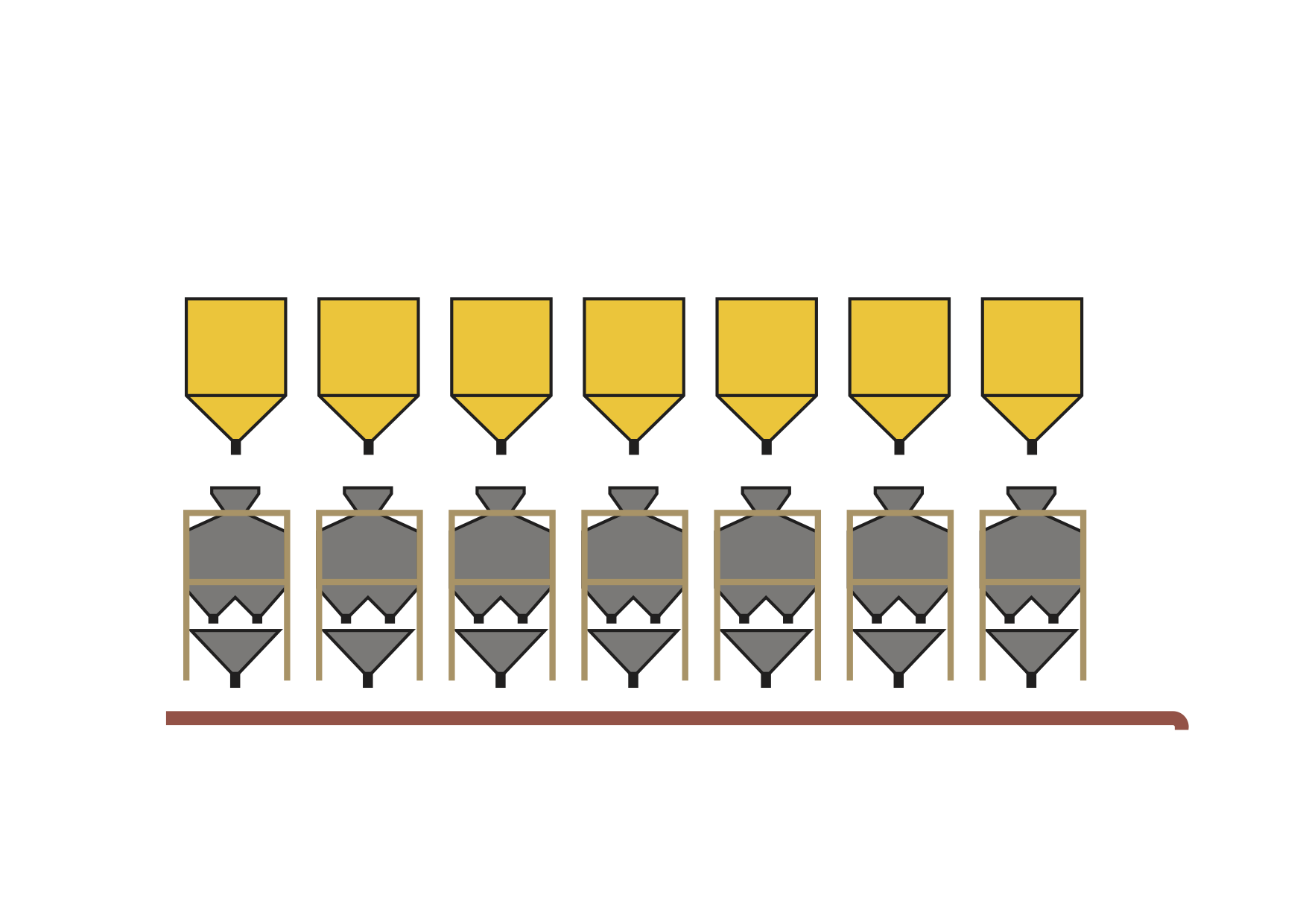

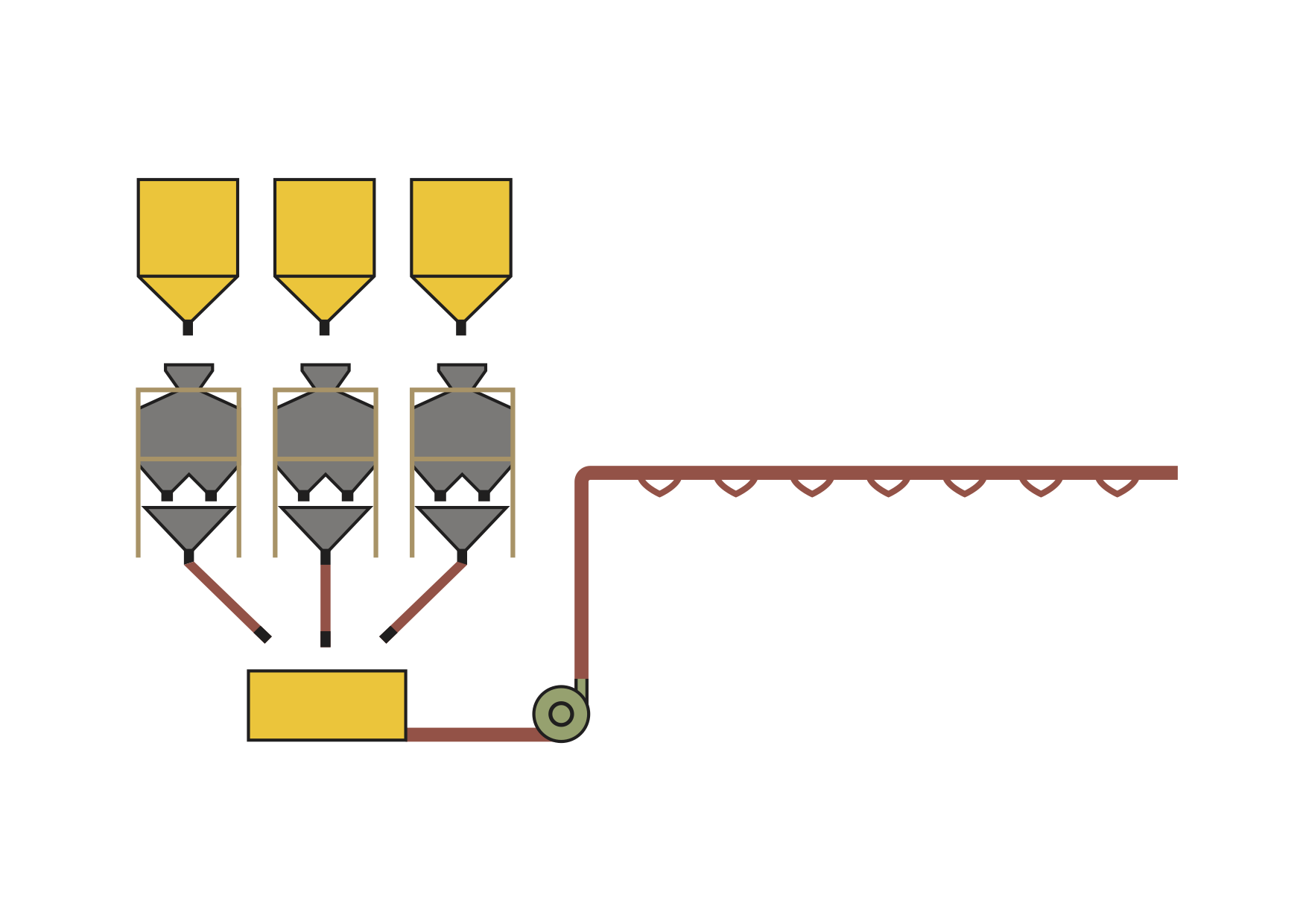

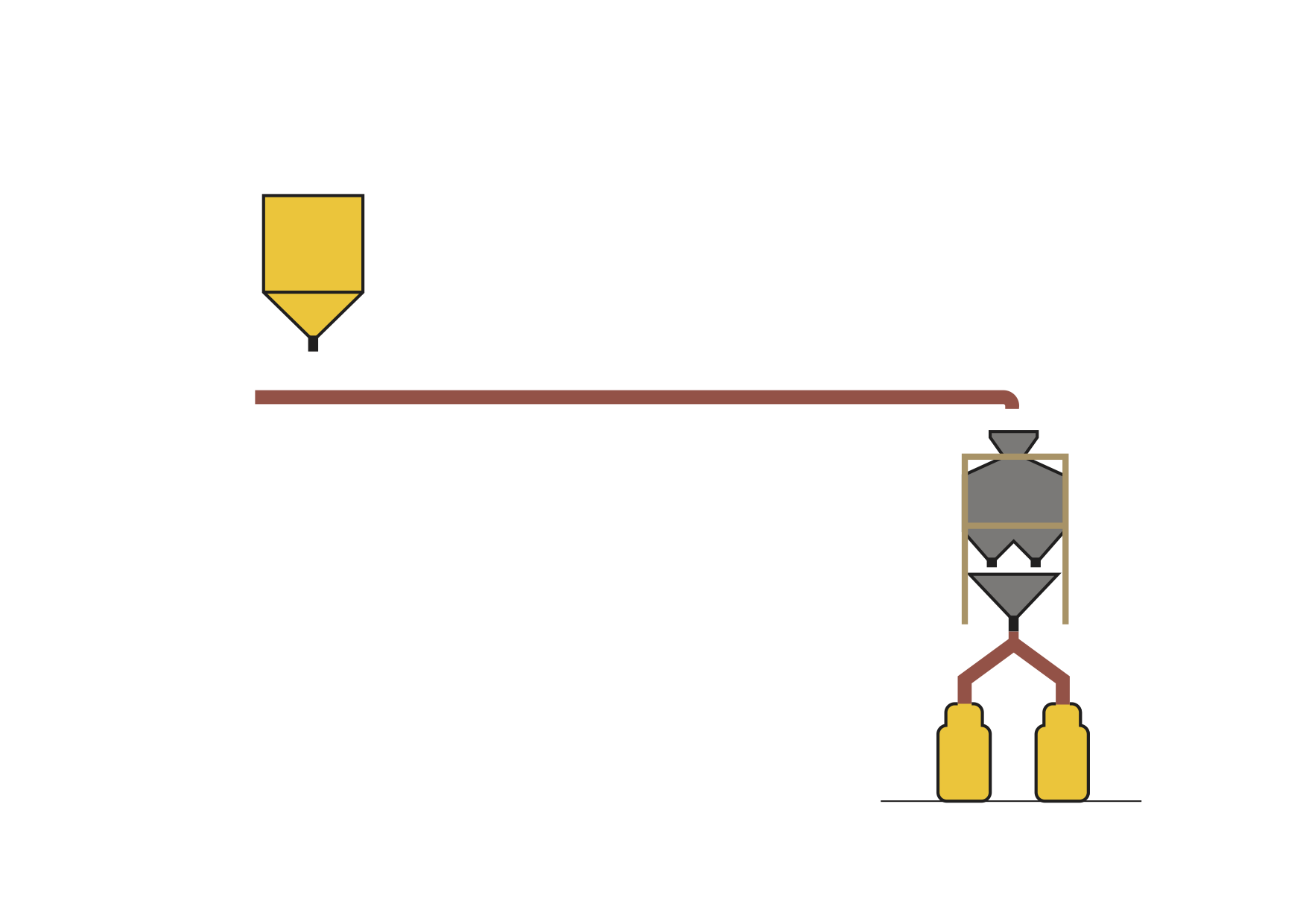

The weighers are designed to be used in connection with conveying systems for weighing in and out from silos, cleaning plants, feeding systems etc. and for weighing out mixed feed or other mixtures in industry and agriculture.

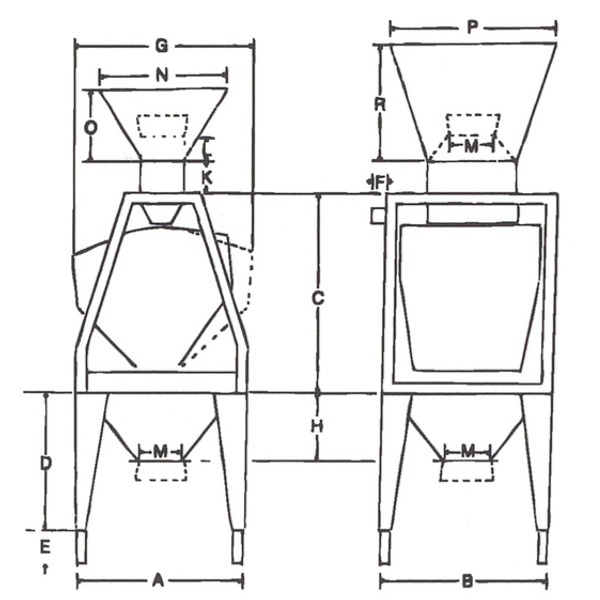

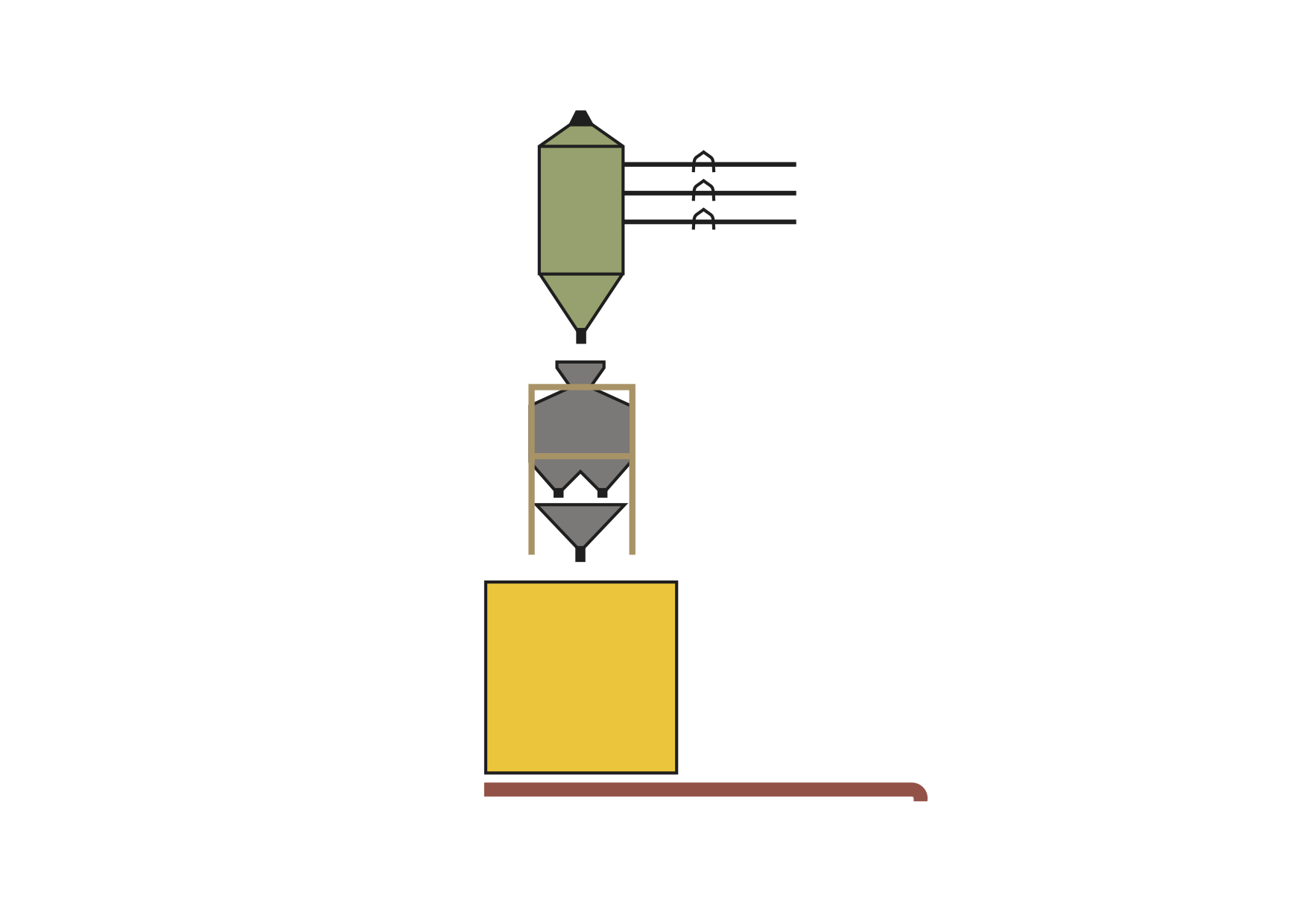

Models D4 / D5

- Control of feed distribution I poultry production where the weigher is installed between the silo and the feeder.

- Managing mills for feed mixture in animal production

- Managing color and material mixture in plastic industry

- Sacking under the weigher of feed, fertilizer and woodchips

- Mixing various granulates in industrial plants

Model D15

- Same uses as D4 and D5 in larger installations

- Controlling quantities in grain works with elevators, augers, conveyors and cleaners

Control of material flow

Controlling the material flow can be done in the following ways

- Starting and stopping the conveying system serving the weigher.

- Opening and closing the electrically or pneumatically operated shutters in the flow pipes.

These functions can be obtained in all weighers connected to an electronic counter with pre-selector switch or other type of electric control.

For weighers types D5 and D15 the same functions can be obtained by using dosage devices types DE and DRE (see Accessories for dosage devices).